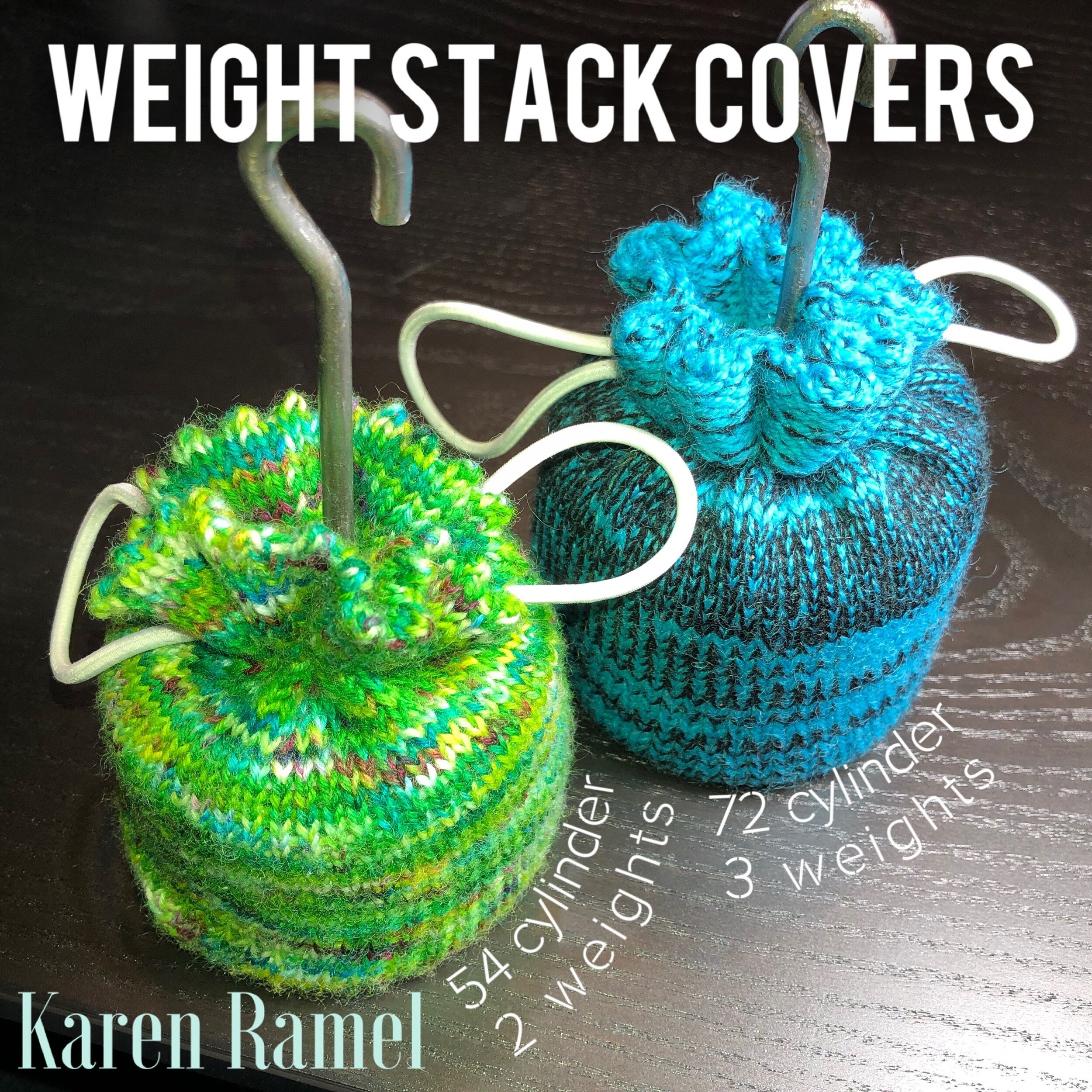

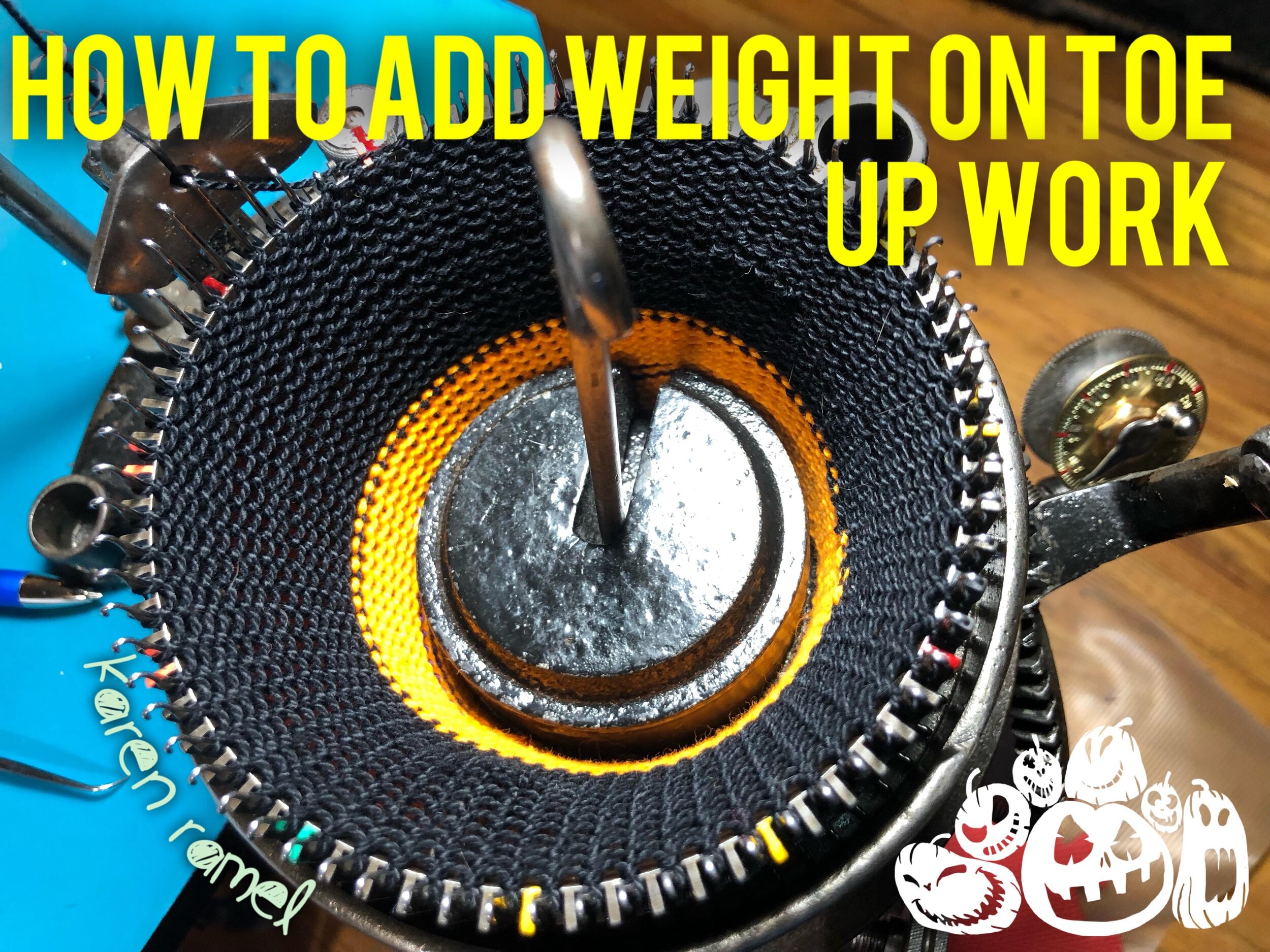

It occurred to me how easy the stacked weights can sometimes mis-align and drop to the floor. Deciding to make something on the CSM which would hold a piece of foam for florr impact padding, I ventured into trying a Toe-Up pouch, working a double project and joining the two as one just before the draw string area of the cover.

See the RAVELRY PROJECTS HERE and HERE

Tonight I finished the CSM: Padded Buckle Weight cover with drawstring.

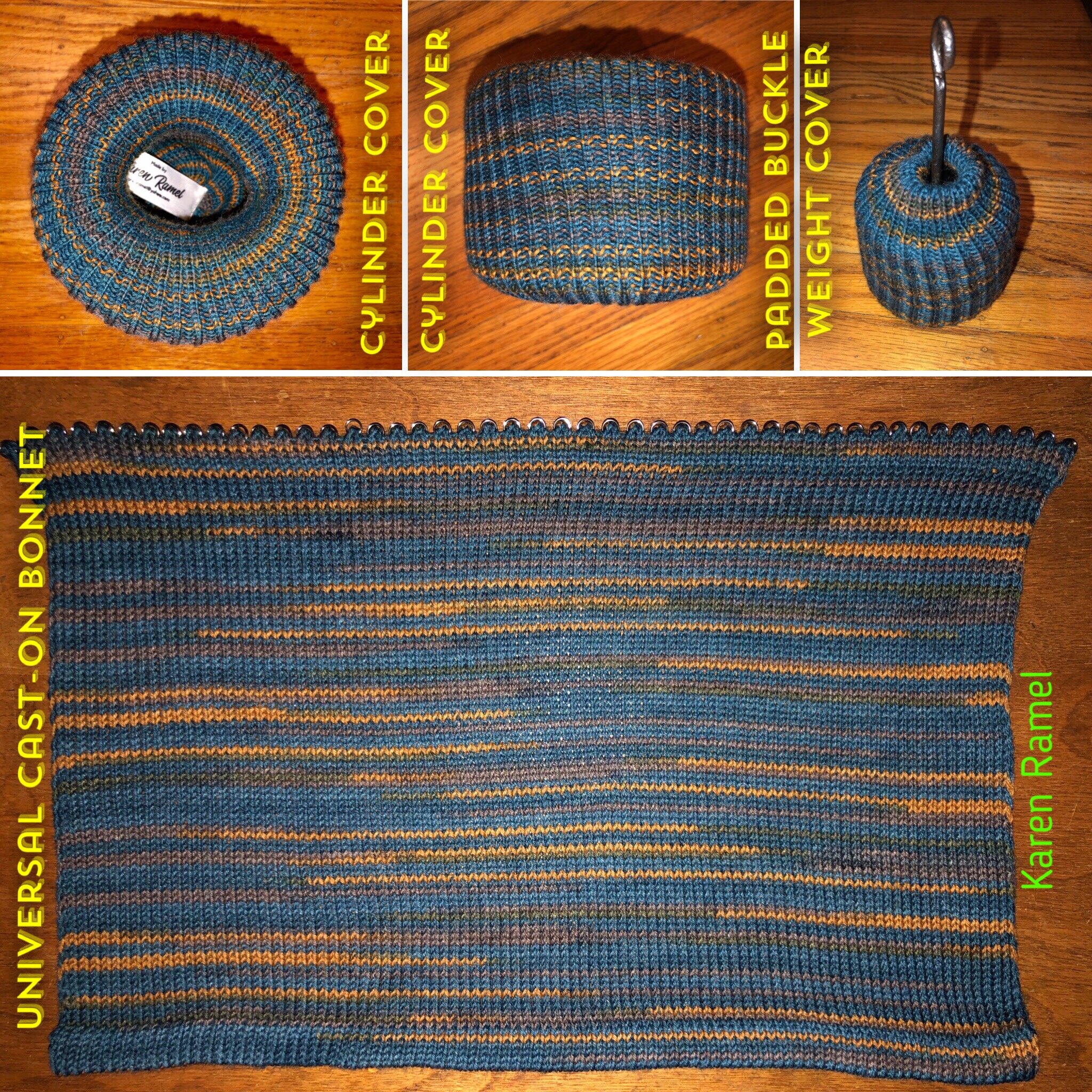

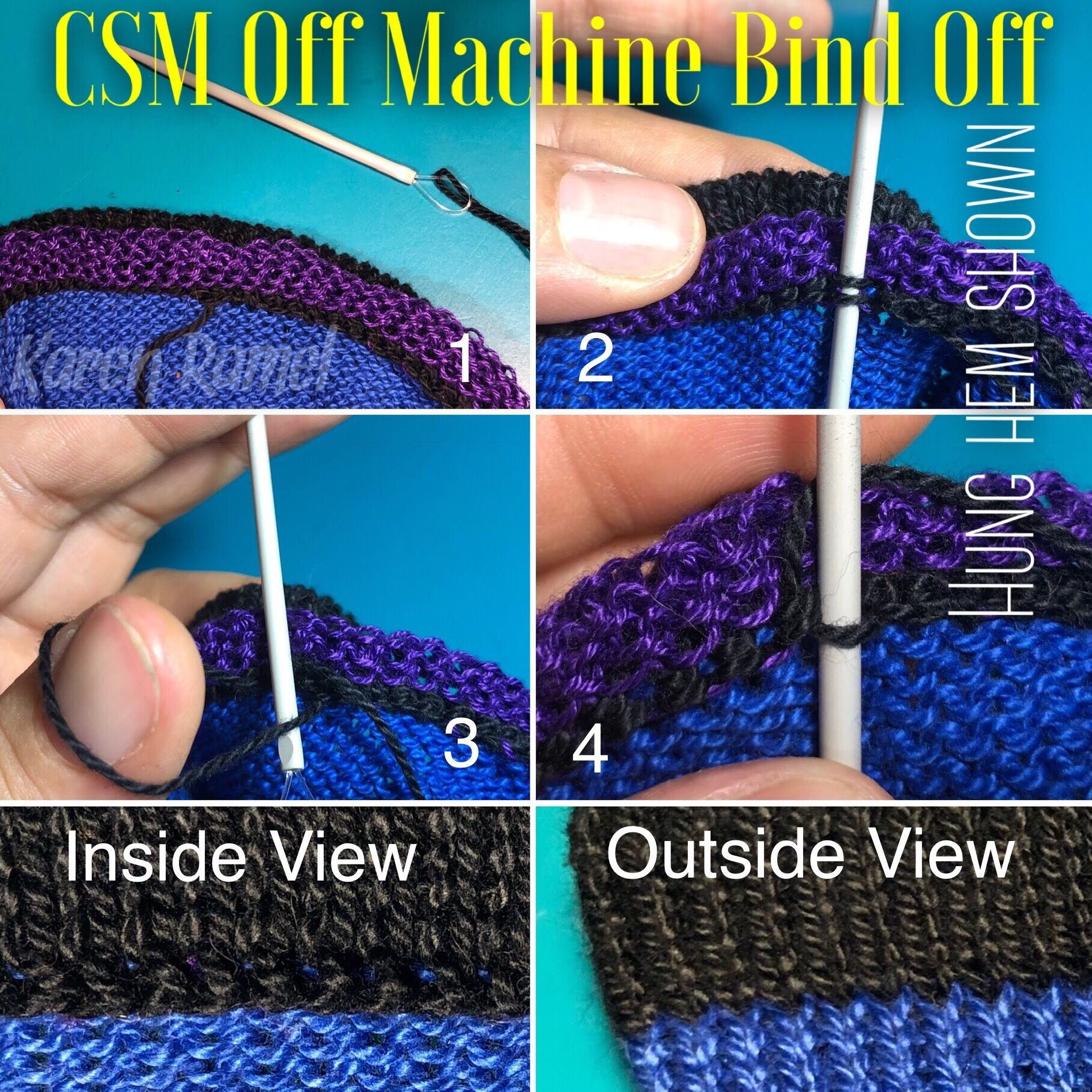

How: Built by first cranking a Toe-Up tube then adding scrap and taking it off the machine, a second same height Toe-Up tube was cranked and then the first was reversed (knit side up) and hung back on the machine. I then cranked 8 rows, did picot (will be drawstring), cranked 10 rows, did picot, cranked 10 rows and hung hem, finished with scrap yarn. Took off machine and bound off stitches. Added a base circle piece of foam then placed the two buckle weights I usually use on the double layer padded bottom cover.

Added stretchy black shoelace style elastic as drawstring. Done. Made on a 54 cylinder Legare 400 without mock ribbing. Lion Brand Sock-Ease in “marshmallow” that I dyed myself.

Photos included below include newer creations for the same purpose and more. :)