Original wood bar-stool purchased from Canadian Tire hardware store (shown below as 1.0 - now upgraded and wood stained). I do not recommend wood stools such as this (even with cutout for the machine) as it becomes top heavy and easy to tip.

Here is the results to upgrading Table 1.0. After upgrading this setup it gained the stability it lacked - widening the supports and reinforcing them, increasing the table top work area.

I donated this wood stained upgraded table at the Spokane, Washington - USA Crank-In Sep 20-23 2019 as I switched to a new style - the adjustable height Ridgid table top system that Erlbacher Gearhart uses in their tables sold on their website.

See my Ideas and Upgrades. | For more info on supplies I like see here.

Posted also on Instagram

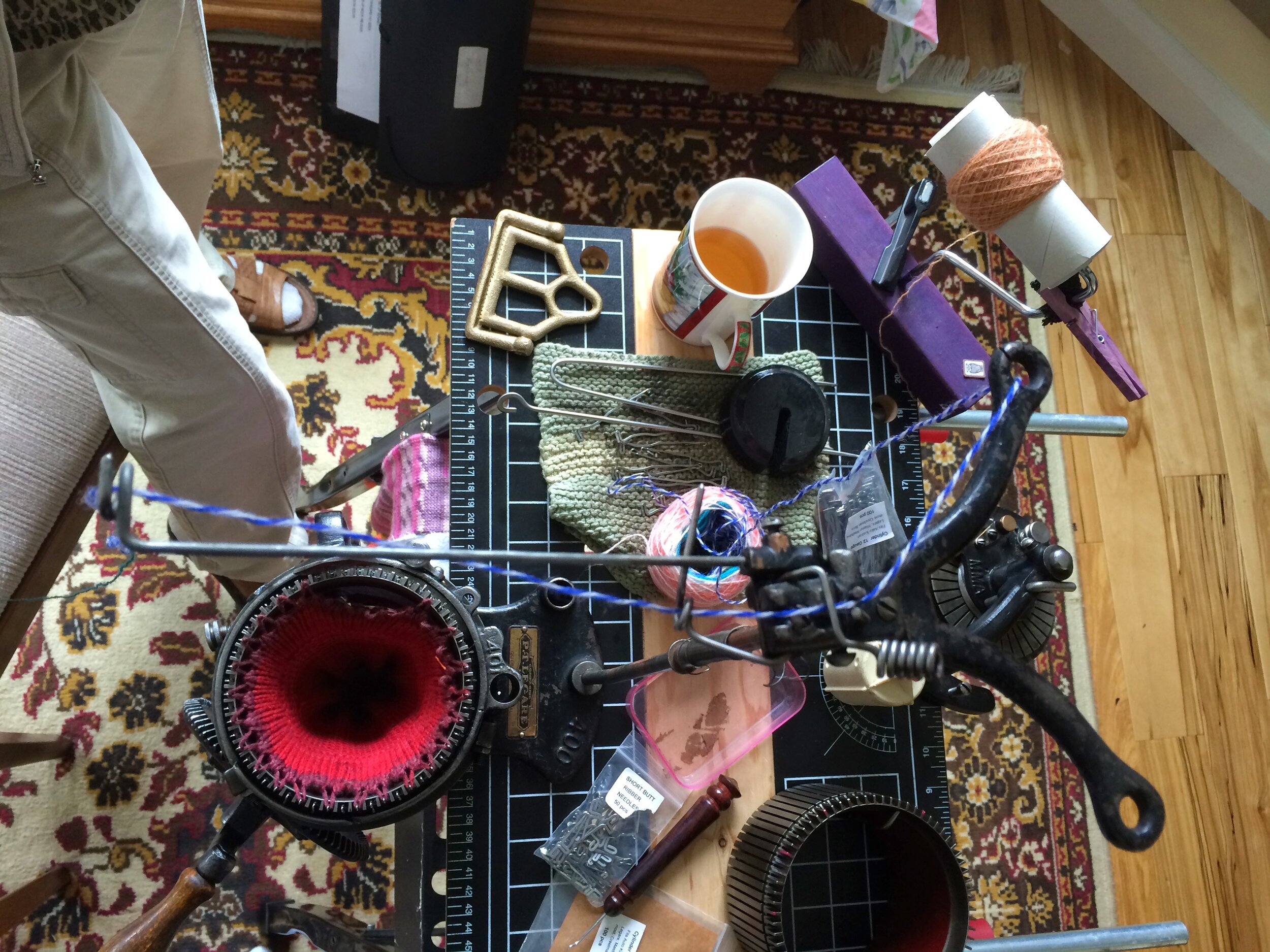

My first table/setup - Table 1.0

My first table/setup - Table 1.0