Introducing the Sock Block & Size!

The minimal upgrade to your Etsy purchased adjustable sock blockers so that NOW they're self stable and size measure confirming. Made a sock and want to confirm it’s the correct size? Adjust the blocker to the foot size and try it on!

These wood sock blockers were purchased from the etsy store: WoodenGiftsCreations.

They come in XS, S, M and L sizes.

I personally find the Small and Medium tend to cover all the sizes I seek.

EDIT: October 2021 as I’ve switched completely to the Katrinkles sock blockers I have given these to a friend. :)

THREE SIZES SHOWN AFTER UPGRADE:

SOCK FORM MEASUREMENTS BY POSITION IMAGE: My measurements as noted may vary from yours due to manufacturing so its better that you measure your own for achievable blocker foot lengths - OR JUST USE THE RULE CHARTS ABOVE by placing sock form on ruler to determine size if the applied sock is sitting correctly!

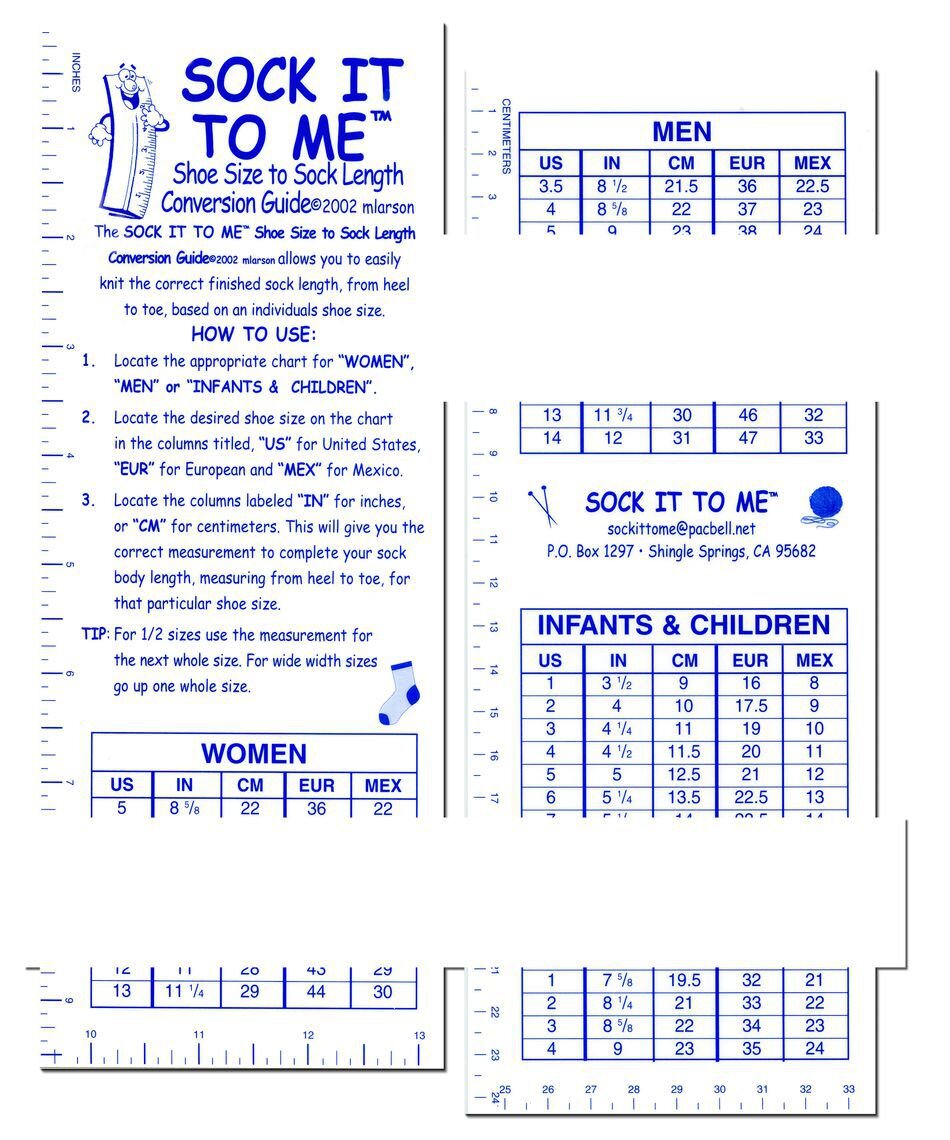

SIZING CHARTS

My currently preferred RULER STYLE charts are freely available at www.blitzresults.com - their exact downloads are MEN US SIZES Chart | WOMEN US SIZES Chart | Kids US SIZES Chart |

The purchased SOCK-IT-TO-ME chart

SEE THE VIDEO | Also on INSTAGRAM