SUPPLIES I LIKE - VINTAGE

Autoknitter, Legare, Vintage Gearhart, Legare Reproduction and European CSMS

This page has been built to help you have the peace of mind that your machine has all its correct components in terms of nuts and bolts. SOMETIMES your vintage machine will arrive lacking the essential nut or even bolt, standard screws may have been changed to non-slotted or a part might have been accidently reversed. Sometimes a nut can benefit the application of a second nut to stop it reversing with vibration/use.

Certainly if your machine now has non-standard screws you can still use your machine - certainly you can - but for convenience sometimes reverting to a slotted screw makes adjusting those screws easier when all or most of the machine screws are the vintage slotted style.

This page is my opinion and in my experience awareness of these basic components HELP. :)

I receive no compensation for any supplier listed on this page or any of these website pages linked to my website.

DOES YOUR MACHINE HAVE ALL ITS CORRECT NUTS AND BOLTS

HAVE A VINTAGE MACHINE? Ensure you have extra nuts and bolts and useful parts - click on images for a larger view.

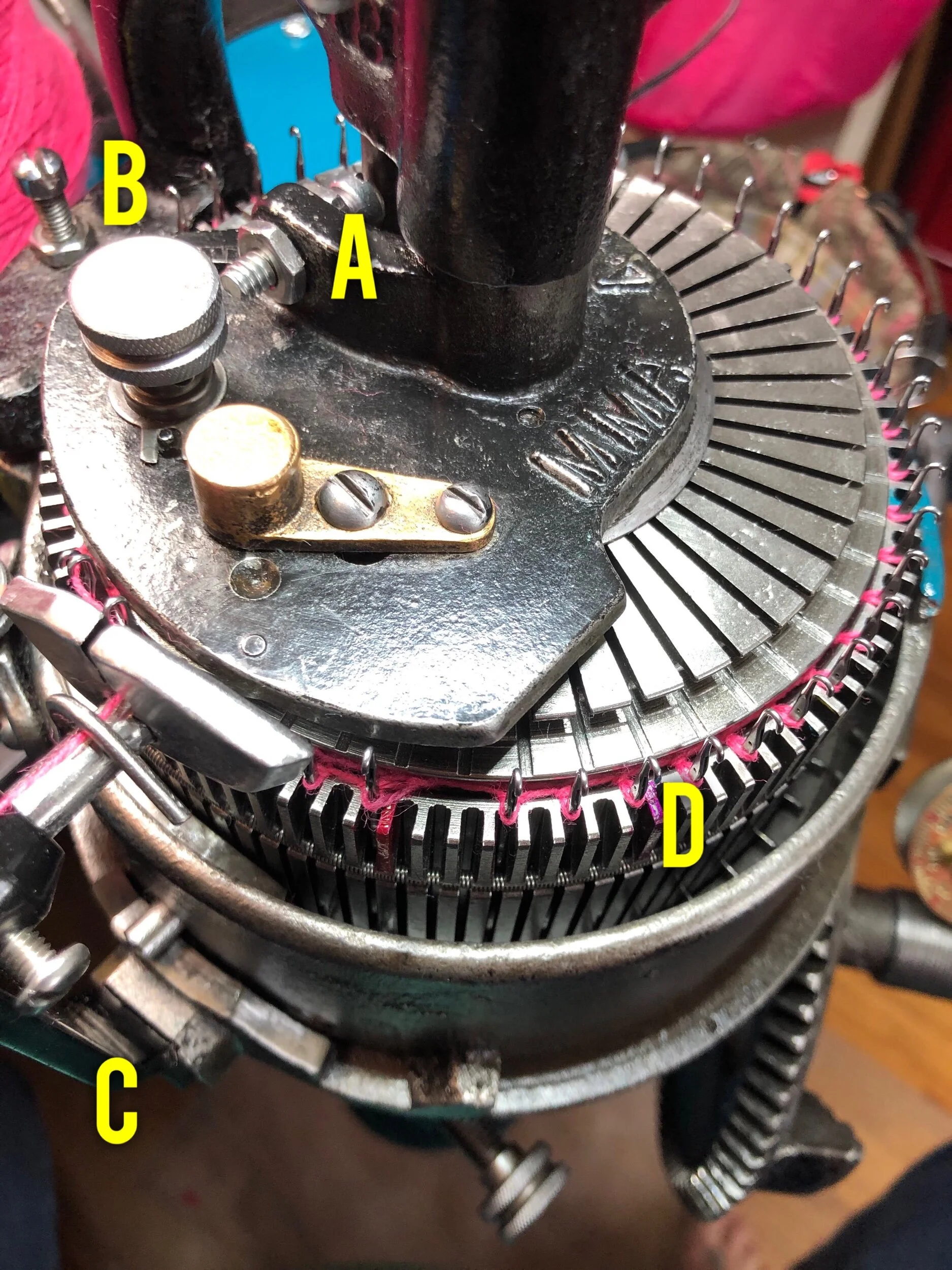

A - obtain a second NUT for your Legare timing screw to better lock the screw in place

B - ensure your Autoknitter/Legare/Vintage Gearhart ribber arm height adjustment screw also has a nut to lock it in place once set

C/E - obtain extra yarn carrier screw and cylinder screws

D - obtain extra cylinder springs (they hold the needles onto the cylinder)

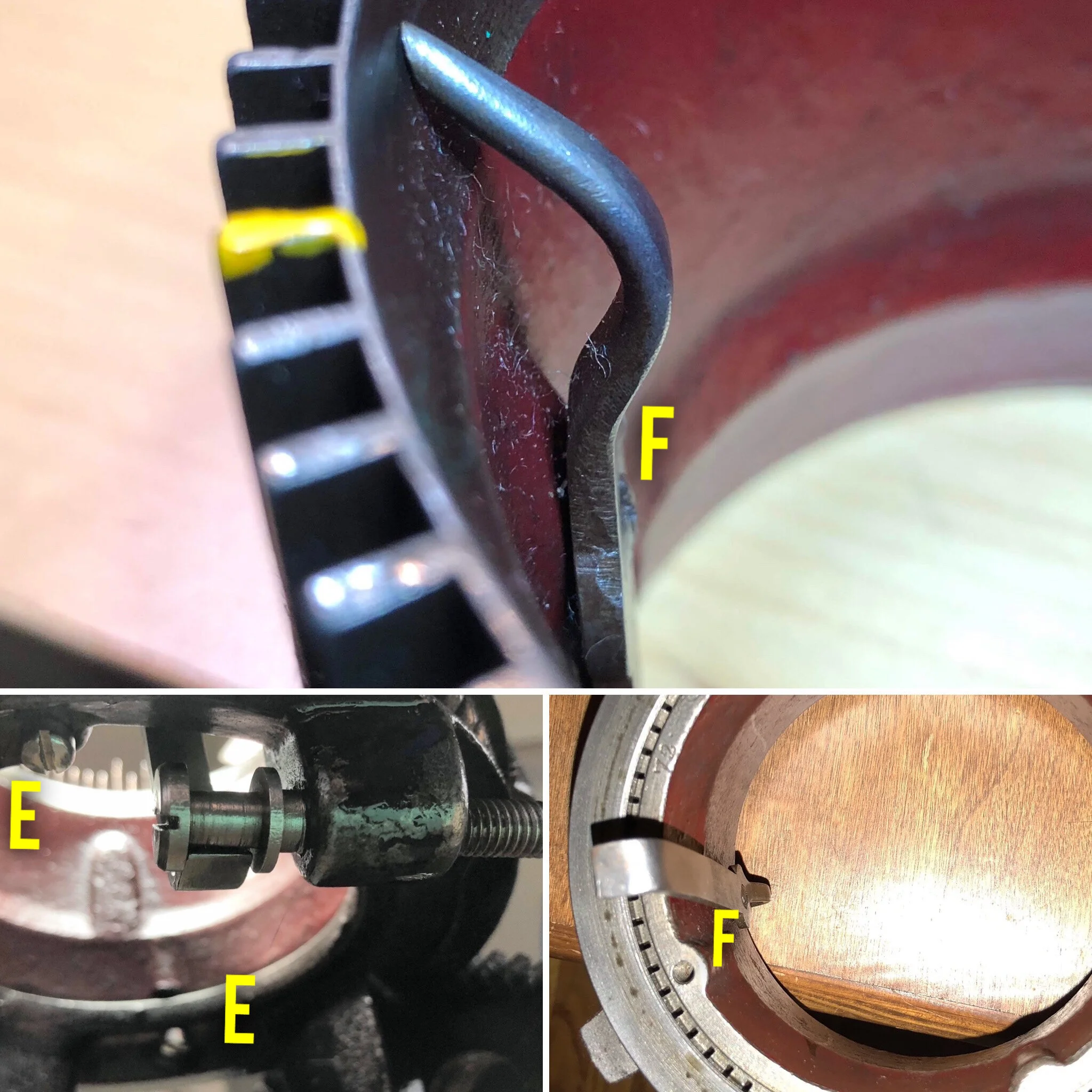

F - obtain a Dial Adjuster (Ribber accessory part - it goes by a few names) and screw for each cylinder you have (vintage inner cylinder profile can differ from the new inner cylinder profiles so having one for each cylinder with extra screws helps). This part is essential when using the ribber as the ribber dial fin aligns to the top part of this item.

The photo on the left is the ribber arm, ensure you have the nut as shown as it helps lock the ribber height once set The photo on the right shows my recommendation in using two nuts as shown on the timing screw to better lock into place, this times how the ribber needles and cylinder needles interact when ribbing. Vibration can cause any screw to move if not “locked” by a missing nut. Note: most screws (but not all) are the same cylinder screw (the ribber height screw is a longer version).

Many of the smaller components are CSM specific in size/thread and may not be available at your hardware store - I didn’t have success on the multiple times I went to our Canadian hardware stores.

Where can one get these items? Dave Lord of Chambord CSM for all listed and Pat Fly of angoravalley.com for cylinder springs/needles etc. See the SUPPLIERS page.

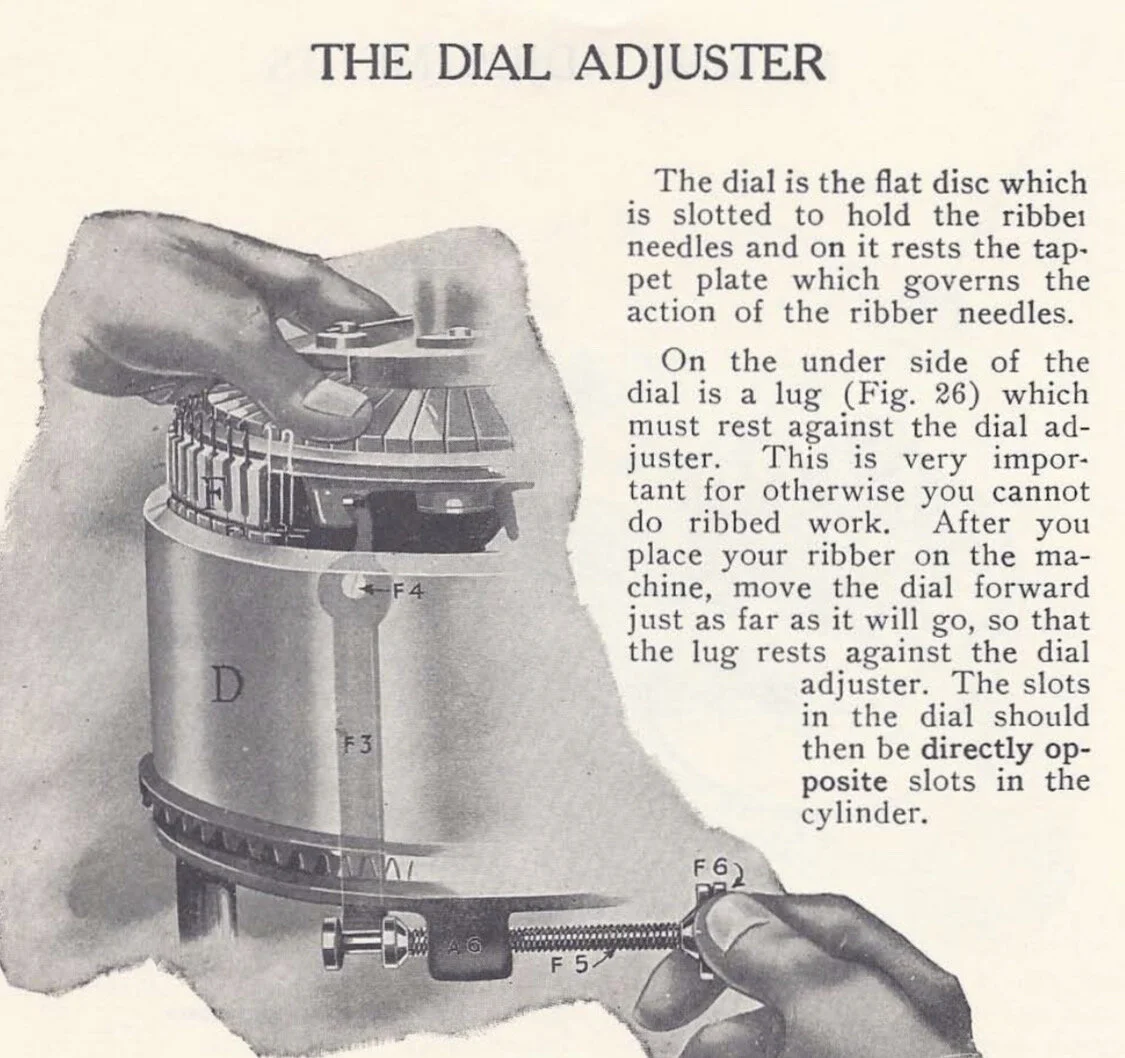

Ribber Dials for these Vintage CSM

Please see the main SUPPLIES I LIKE page for the Ribber Dial Designs segment.

HAVE A LEGARE?

Do you have a OLDER or a NEWER ONE?

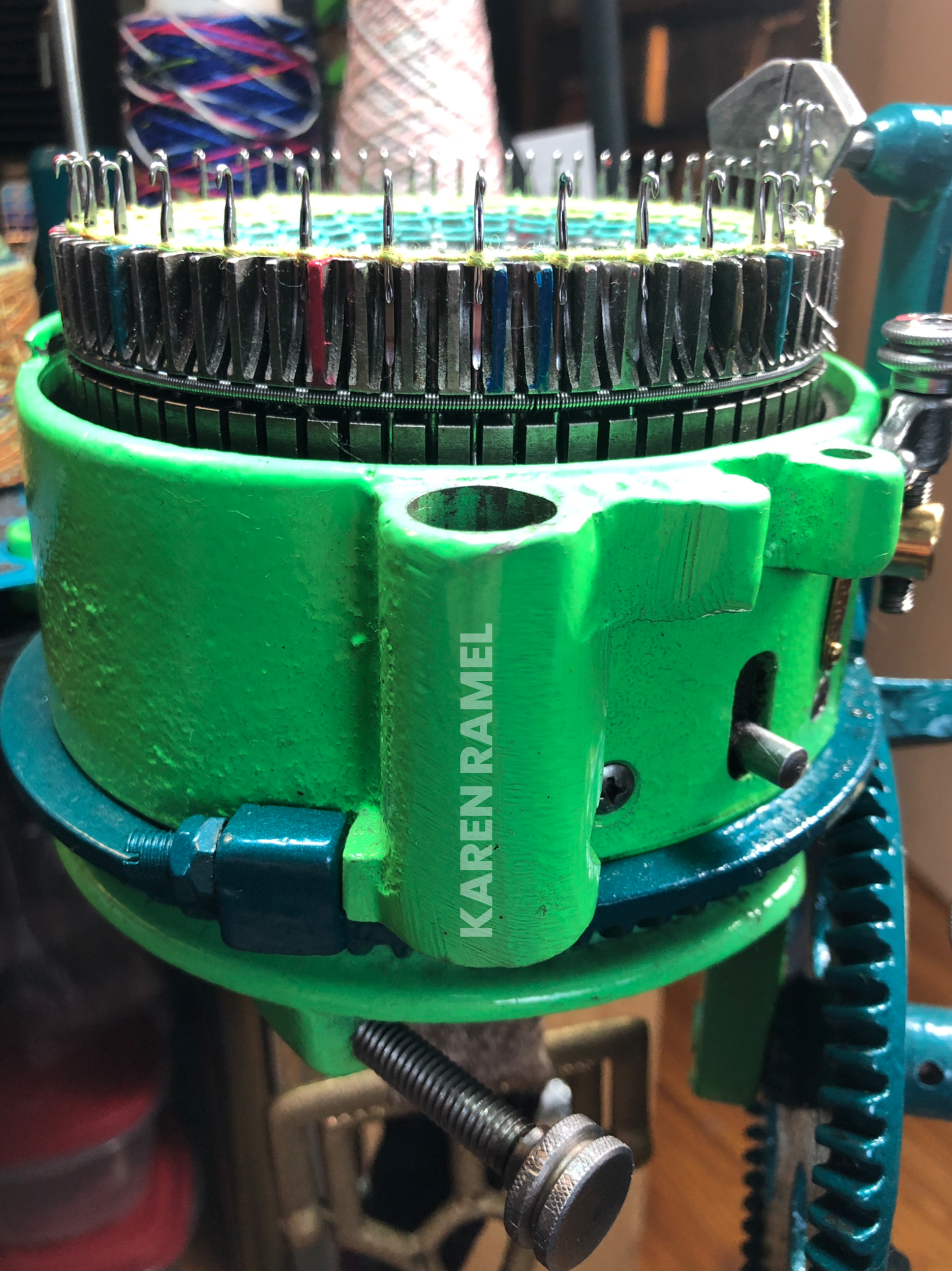

The newer version has the YARN CARRIER TIMING BOLTS WITH NUT on the COG RING (the COG RING is the flat round part that connects with the crankwheel to move the machine in either direction).

If your timing screws with their nut(s) are reversed on the mount, if they are over/under adjusted or missing (and/or not best secured with two nuts) you may not have success trying to knit as the knitting WAVE won’t be in the ideal position.

My machine has the newer version. Here are photos for clarity. A OLDER machine is shown as a drawing for clarity, the green images of of my newer machine. The COG WHEEL on my green machine is the darker green part you see.

Within the last 36 hours I’ve helped two persons with their newer Legares.

One person had the correct timing screw bolts and nuts that somehow were installed backwards, the other person had both bolts but only one had a securing nut and both were maladjusted. In BOTH scenarios if all else was right and they were trying to cast on they would fail as the area to best knit would NOT be in the ideal position at the Yarn Carrier.

This lower right best shows the YARN CARRIER TIMING BOLT connecting with the bright green ribber mount. At this connection you see the machine is pushed to work in the regular forward motion (which is counter clockwise knitting). The other side of the machine is where it connects to go in reverse (clockwise knitting). If either are set with a bolt too long/short then there might be stitch malfunctions.

For more machine information please see my LEGARE page.

Have a question? Please email me karenramel@yahoo.com

We STRONGLY suggest getting a full manual for your machine!

This VINTAGE page is now complete.

Please refer to the general SUPPLIES I LIKE page.

Have a question? Please email me karenramel@yahoo.com :)