I started with the thought about using a Singer Sewing machine to use Treadle Power to aid in using my Circular Sock Machine, however after much thought we’ve decided to revert to our original plan of pedal powered. For more info see the blog entry TREADLE POWER

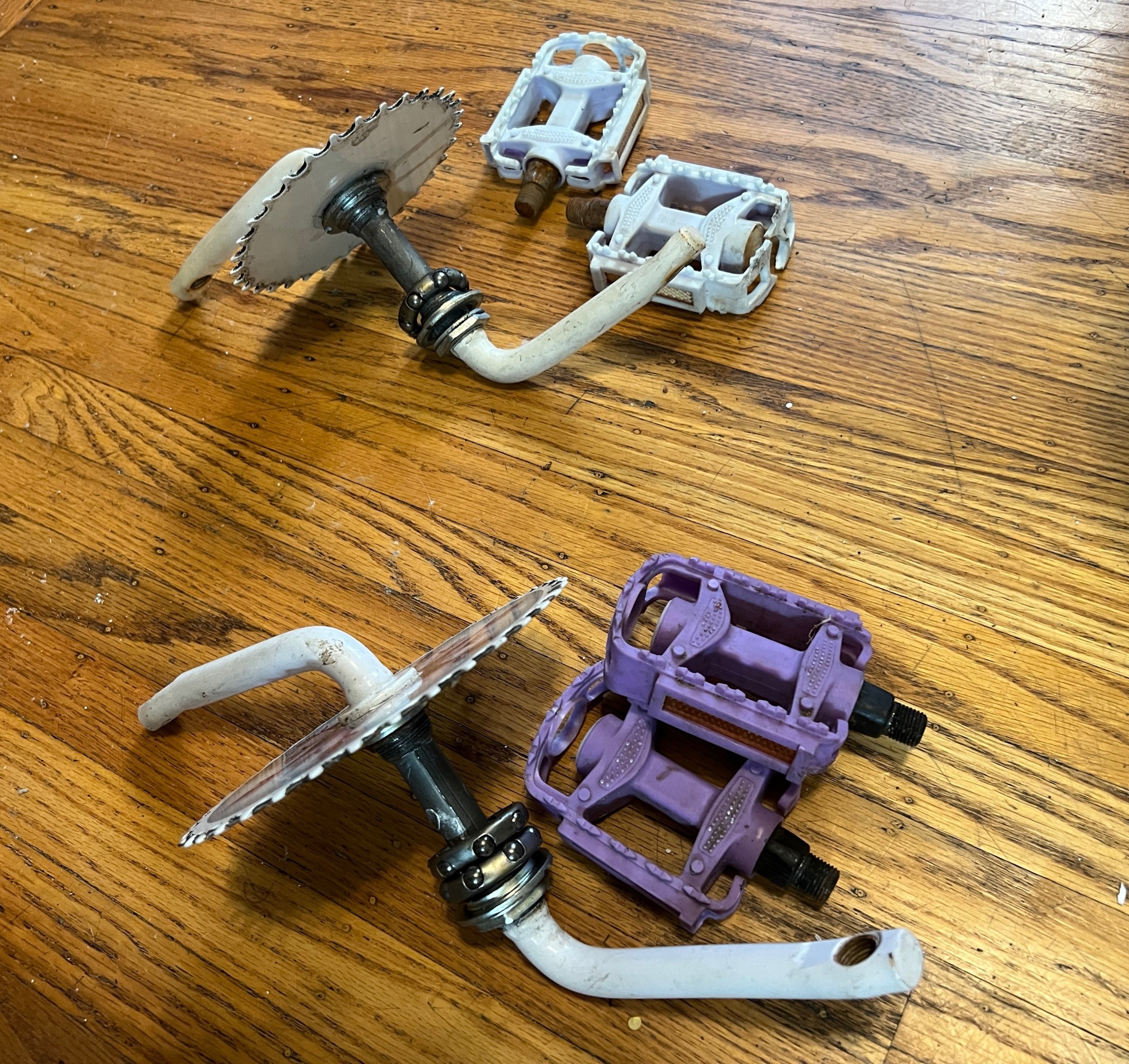

On the right we see the used and forgotten free bikes picked up for free from Craigslist a couple weeks ago. They’ve been living on our patio while awaiting their next step. Now it’s time to begin this project.

First I will harvest all the usable parts and clean up what I can. Note that all of these were in very poor shape as bikes.

Our wonderful neighbor Ron helped using his chain tool to open and connect two two chains into one long one (that can be length adjusted another day). He also helped dismantle the pedals to prep for frame cutting and the back wheel gear with teeth.

The gear from one bike had 18 teeth while the other had 17. Holes had hoped to reuse and mount onto the crankwheel to have the chain turn the crankwheel but now realize I have no easy way to connect the two pieces.

These are the two pieces (one from each back wheel on the two children’s bikes).

So I measured my crankwheel where the gear would mount and went onto Amazon for a gear I could install myself. No success.

Our neighbor Ron dismantled the pedal areas of each of the two bikes - good thing too as both lacked ball bearing grease and one set ended up uneven when one of the two broke. (See photo)

I went onto Amazon to buy ball bearing replacements (no luck for now but that’s okay as the ball bearing part is for the extra setup not the main one I prefer. In the future I will look for that if needed). I bought grease to reinstall the pedals after the frames are cut down.

Tomorrow I will use my Dremel and trim each bike frame so that each can separately self support the pedal part.

Mon Sept 5, 2022 - Today using a Dremel, I cut off the unneeded bicycle components and did a bulk finish of the edges. We now have ONE (currently blue/green) setup plus a BACKUP version (currently pink).

These each will hold their pedals and once finished, each will connect to chain that will attach to the component on the crankwheel.

I didn’t cut all of the proposed metal off each part yet, choosing minimal alterations at this time. If during trial use it turns out I don’t need such a robust bike frame design I may then remove the excess as per the plan previously shared.

Now we wait for the new specialty ball bearing things for inside the pedal mount, the lubricant and the gear part that hopefully will connect to the extra crankwheel I have. These parts are ordered from Amazon.ca and are due to arrive Fri Sept 9, 2022. I have additionally ordered two other gear components from eBay but their delivery is estimated at the end of the month.

Sat Sept 10, 2022 - This morning I reviewed options and outcomes. Next step is to attach the gear from the inside of the back wheel to the crankwheel in such a way so that the row counter can still be used. ;)

After running an errand we stopped at the hardware store for these supplies.

I originally considered drilling holes and making them threaded but I decided to keep things simple after the hand driven tap tool broke off in the hole. Nothing I tried helped so I settled on leaving that screw hole empty (or hiding that with a fake screw head).

The first screws I tried were 5/8 long and too short so back to the hardware store for the two shown. I found while initially assembling it was easier to use the longer screws however once assembled I switched to the 3/4” length (opting to not use the tension washer and extra washer).

Sun Sept 11, 2022 - today I realized I probably do want to trim down the remaining bike extra segments (but that this is not happening today) so instead I focused on using what I have to stabilize the pedal segment as by itself it’s tippy. I noted further that best chain alignment requires the pedal segment to be exactly stationary without movement. I didn’t have the wood and didn’t want to go find some so I used a shelf from one of my tables - rationalizing that it could do double duty. After much work on that shelf as a stationary mount - it just isn’t the right solution to this setup. Our neighbor Ron brought over his chain tool and joined the ends of the chain for testing.

We picked up a lovely height adjustable bar style chair to aid in using the machine with the pedal setup

Today I also realize that it would be a benefit to further adjust the large washer on the crank-wheel connecting the gear -the washer isn’t seated 100% parallel causing a slight uneven seating of the chain. As these components are attached with five screws, it would be easy to dismantle, readjust and reassemble - perhaps with a better clearance for the row counter. Below are two mock up images as it is right now.

I’ve outlined current thoughts on chain alignment and board layout with cutouts for the table legs to sit through. The board might end of more of a triangle than a rectangle.

Next step: another hardware store visit for a board

I have some things on my calendar in the next two weeks that might mean putting this project on hold. Will see.