The experiment: Using a new Chambord CSM Accuknitter (a closed Cam machine similar to the vintage Legare), a 72 needle slot cylinder and a 72 needle slot ribber Pro-Series dial, I created five identical pairs of Cuff Down Ribbed socks where the only variable was the slight change in the Tension Dial setting (half a turn). Sizing for me is always done after sock wash and hanging to dry. For more on what a Tension Dial is see CSM Start-CSM3.

So let’s review the details.

The exciting results: each identical pair of socks were ONE size bigger with only the half turn of the dial being the change (with this yarn, this cylinder and ribber and this machine with its CAMS).

Cuff to heel lengthening? Also observed on each sock was the measurement from the heel seam to the top of the cuff, generally with each half dial turn, the sock increased in a measured way from cuff top to heel seam apex by 0.5cm (photos showing cm and inches for the T4.5 pair are shown)

Correct foot self striping patterning? It’s interesting to see how the self striping misbehaved on the heel spring applied foot segments of the socks using 2.5, 3 and 3.5 dial turns but rights itself on the 4 and more dial turn socks. Without running this experiment on another color-way there’s no way to verify if this is what always happens using the same properties followed here.

Diameter? As I have no current way to measure how much more stretchy in diameter these socks are (other than shoving my foot into each for a non-scientific result), I have noted that my theory on how the diameter stretch did seem more comfortable, possibly noted over time and many washings as a more comfortable pair (but only to a point). I was surprised at how each pair worked up and looked at each dial turn as in the past I ONLY ever worked at two dial turns and assumed anything more would be too floppy - not necessarily true.

Why is working with Tension Dial settings is helpful

If you ONLY have 100 grams of sock yarn, knowing how much less (or more) yarn is approximately used by simply tightening or loosening tension stitches can help.

Common requests include how many rows a certain sized sock requires… machine settings, yarn properties and sock design tell us that any way you look at it expect to take notes and adjust as needed.

This experiment shows that I was able to create socks easily from a US Women’s 6-10/Men’s 5-9 using the exact same row numbers and basic method and still used less than 100 grams of sock yarn for each pair.

A CONSIDERATION: In the past a swatch perhaps using all the Tension Dial sizes was recommended, BUT I recommend considering making yourself BASELINE SOCKS in your most average sock yarn with just the Tension Dial changes, washing/drying and sizing. Then going forward you can use that sock and those settings with that same style yarn to determine how many more rows or less to make the size sock you wish. :)

Ravelry #182 - T2.5 - 82g - 6W/5M

Ravelry #178 - T3 - 82g - 7W/6M

Ravelry #179 - T3.5 - 86g - 8W/7M

Ravelry #180 - T4 - 87g - 9W/8M

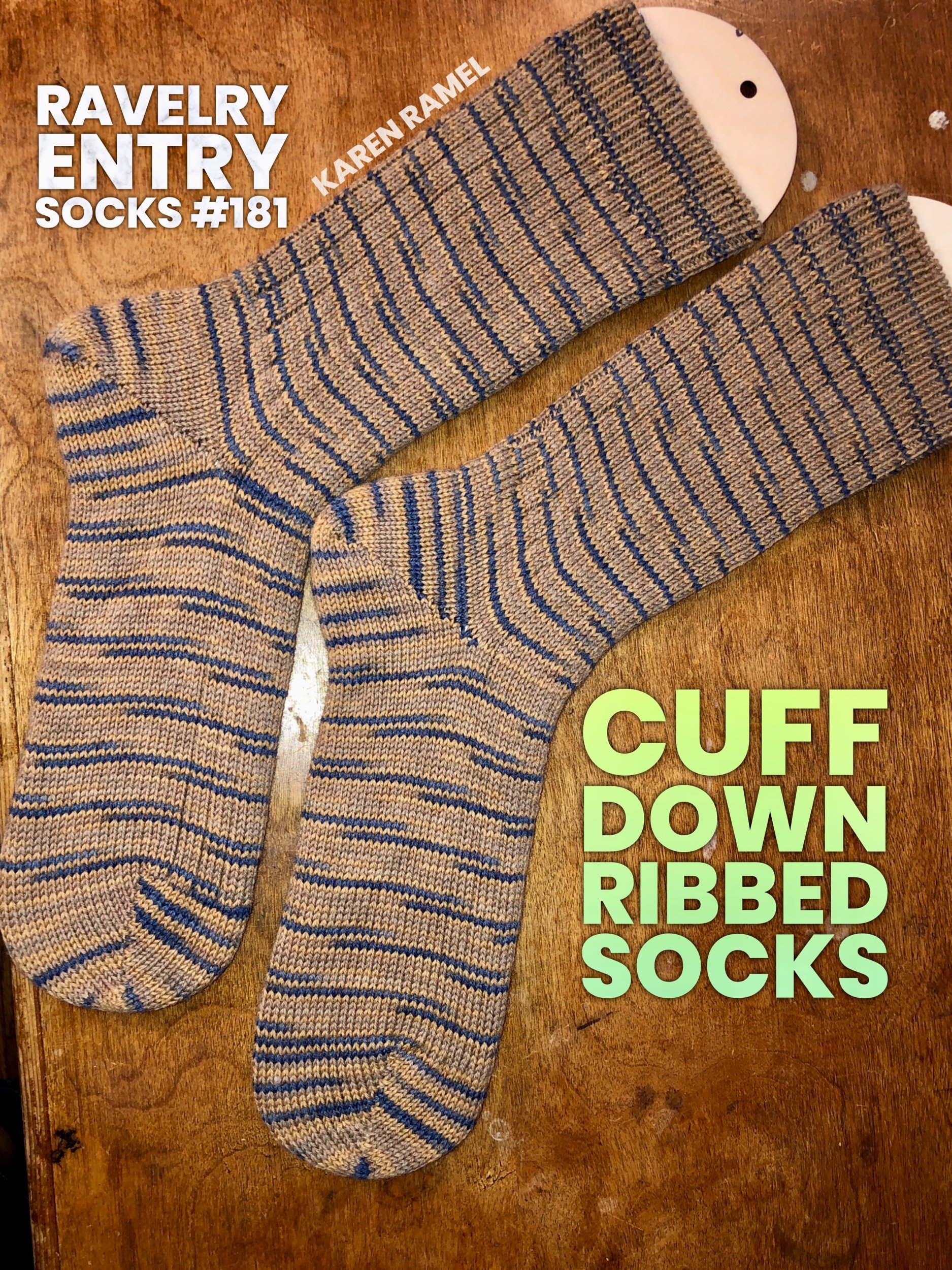

Ravelry #181 - T4.5 - 91g - 10W/9M

REFERENCE:

Socks shown with a number are referring to their Ravelry project for anyone wanting to see that project on Ravelry.

T refers to the TENSION DIAL with its number of dial turns from the tightest setting with the yarn on the machine.

Numbers shown with a ‘g’ indicate weight in grams of yarn used for those socks**

The “W” and “M” numbers refer to the confirmed sock sizes for Women/Men.

Gauge of Stitches and Rows on each finished sock are noted _R/_S

Note: **I don’t have a secondary way to verify project yarn usage by weight but the rest of the findings have been verified multiple ways. (I am not 100% that the food scale is perfect)

Click on any image on this page to view a larger version. Note these socks have the 2.5 dial turned sock on the far right, proceeding half a dial turn on each single sock shown to the final sock on the very left at 4.5 dial turns.

Note all socks had the Heel Spring in use for the Anchor Yarn Tail Technique, SELVAGE/Welt and segments from the Heel to Toe.

A NOTE ON TENSION DIALS AND CAMS: Although my experiment was run on my closed CAM Chambord AccuKnitter - which is very similar to a vintage Legare - (the tension dial is shown on the upper right), EVERY machine has something you turn to adjust how tight or loose stitches are. As a side note, open CAM machines like vintage or modern Gearharts and Autoknitters, their Tension Dial often can be adjusted much tighter or looser than can actually be knitted.

This means my machine and dial turns might not be the same as your machine (even if the same make/model) HOWEVER when you work YOUR socks on your setup, yarn and settings, consider that simply turning the tension dial one way or the other might also translate a size increase on YOUR sock (when using exact all else).

Experiment!

To be successful in making socks on a CSM you have to be able to know how to set it in a way you can reproduce. A stitch range any CSM can work depends on its V-Cam design. See the MISC menu for the MISC CAMS. Some people use a digital caliper to determine settings - I find using dial turns more reliable

Summary of techniques covered in these socks

METHOD DETAILS ON EACH PAIR:

Cuff Down Ribbed Sock summary: Heel Spring: My Anchor Yarn Tail Technique then still with Heel Spring: Selvage/Welt 1 row in work, 2 rows out of work, 1 row, Heel Spring removed: 20 1x1 rows on the cuff, 60 1x3 rows on the leg, 10 pre-heel rows, Heel Spring from here to end: no-wrap heel, 60 row foot, no-wrap toe. For free pattern, video and specific techniques see my PATTERNS AND VIDEOS menu on the homepage.

Where can you get the Katrinkles Adjustable Sock Blockers that you can add your own equivalent size labels? See SOCK BLOCKING AND SIZING on my SUPPLIES I LIKE page.

Where can you get information on how to CAST ON with your CSM? See my CAST ON page under my CSM LEARNING menu on the first page.