Dave Lord’s Chambord CSM “Set of Main Weights CHA224” as shown on the left are a total weight of 1663grams or 3.6lbs. These style weights hang under the machine usually from a buckle.

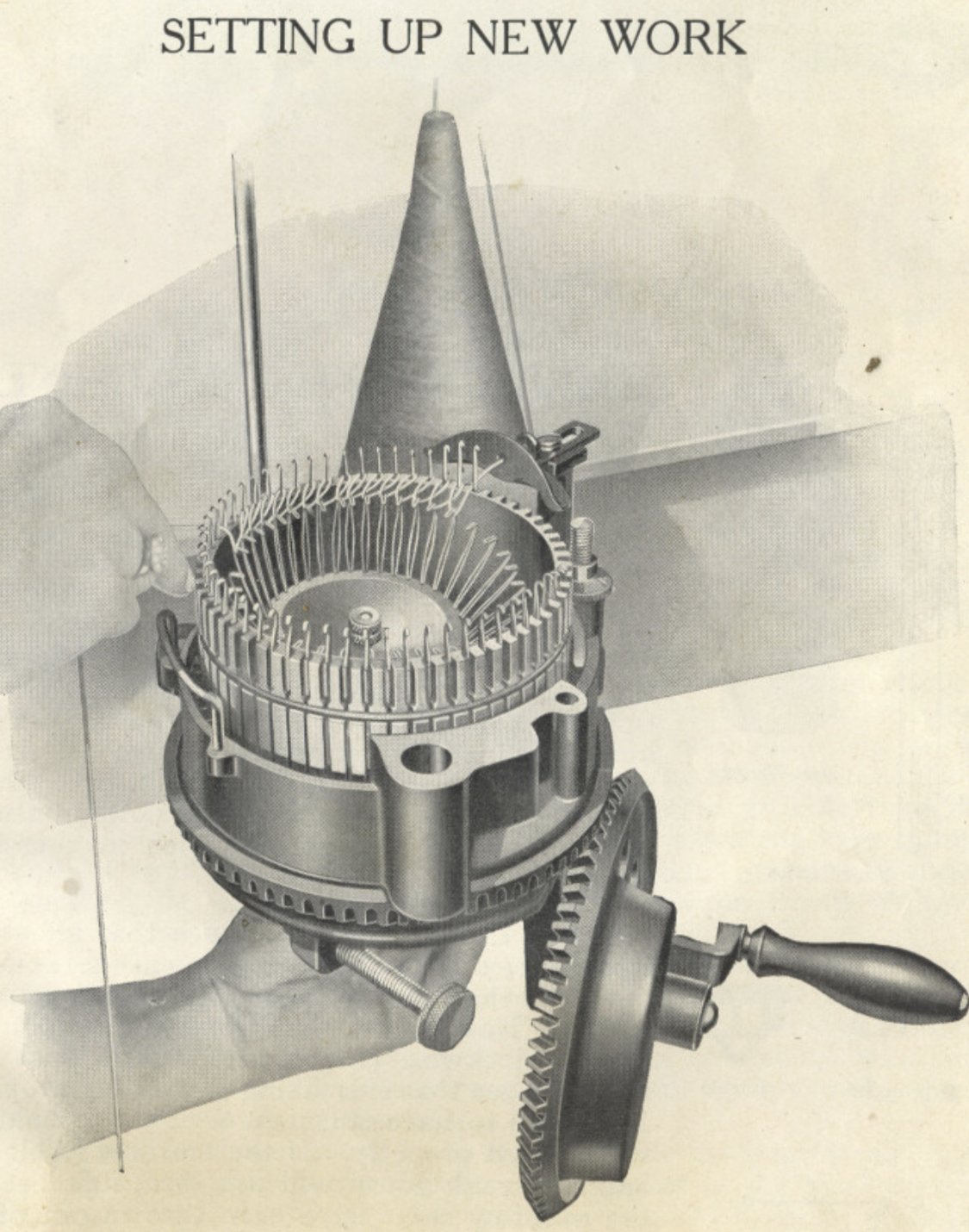

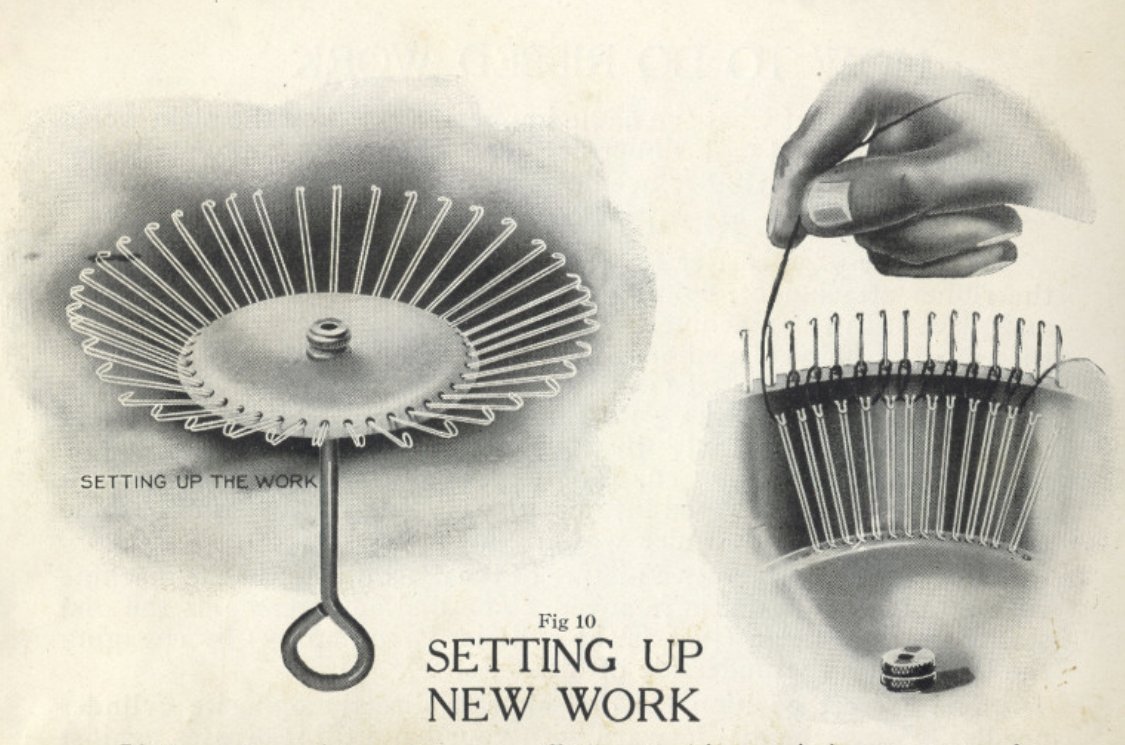

ABOVE: Shown here on the left is a vintage version of the weight stack shown with a pulley style top. I’ve included a detailed image on how it was used - it’s used for the TOE - not as a standard full machine weight. On the right the same V Hook was used for the Heel/Toe but with a regular stem weight as shown.

BELOW: My vintage Legare 400 came with two weight stacks which included pucks of two different thickness and weight (to be used above on the right). With todays fiber and method we use what is shown below. Having a fully weighted stem weight now seems excessive for the Heel/Toe.

Soft Weights

These can be used on Toe Up or Cuff Down Socks.

The lovely Dean & Bean 3D printed machines suggest using soft weights placed on the inside of the cylinder. A soft weight is basically a weighted bean bag style of weight. There are many videos on making soft weights - google search “CSM soft weights”. See their contact info on the NEW CSM Machines page.

PRO: a benefit to having weight(s) placed on the inside of the cylinder (instead of under the machine) is that the clearance under the machine doesn’t have to be as big.

CON: Weights need to be completely centred and ensure during use that they’re not snagging or being hung up on the inside of the cylinder itself. Also the soft weights are bulky so working a toe up sock with a soft weight on the inside means you don’t have the clearance on the inside of the cylinder to add the ribber (if you wanted to start rubbing on the sock there).

My personal preferred weights remain the stem weights/weight stack using a buckle.

Heel and Toe weights

The Chambord CSM SweetSpot V Hook and Weight

The modern and upgraded V Hook Heel/Toe system is used under the machine. The V Hook is applied and the weight hung. The weight itself is 1002grams=2.2lbs

This is my preferred system See how they’re used or order one yourself by checking out my info page on Chambord CSM and contacting them via email to order.

See the picture at the top of this page for how it looks with this weight in use.

The newer company Dean & Bean created a TOE UP weight they call the V-Hook (not to be confused with the vintage V-Hook weight). A Toe-Up weight can only be used if using a cast on bonnet that has a closed bottom section (or ring) or if having cast on, one is working a Toe up sock. See further down this page for a visual example of that weight system.

Heel Forks

Generally a three piece system used to add specific weight to the project at specific parts (like making a heel or toe). Each weight is about a pound each.

Personally these are great but more pieces to manage means more work with more items meaning less room to apply under the machine. Before using the V Hook and Weight mentioned above, I created these which made them easier to place with their minimum hook design and easy way to tell which way the hooks are without needing to see them. See more cool Ideas and Upgrades.

This next section isn’t about the amount of weight but rather how one can add weight in this specific scenario/project.

Toe Up Weights or Weight Systems

Next let’s review some cool ways to add weight to a Toe Up project allowing for easy ribber clearance install (for when we want to add the ribber on your sock after the toe).

The benefit of a hard shaped weight placed inside the machine (like a soft weight) is that it generally won’t get caught up on the inside of the machine.

However having weight applied from UNDER the Toe Up Sock seems to be the BEST way in my opinion. Here are some examples and ways to do that. Vintage Circular Sock Machines came with a reverse umbrella like item named the “Start Up Device” which was used to cast on. There are modern reproductions of that start up sold even now from some suppliers. (Click on any smaller image to view full size).

See my Jan 12, 2020 instagram post

I then noted a wood disk version (the wood disk from a piggy bank project) in a video and decided to create my own metal version which was lower and more minimal in the project. For more Ideas and Upgrades. The above image shows the video screen shot and my initial version. I then asked the lovely Dave Lord of Chambord CSM to create a metal version (shown on the right).

The benefit of hanging weight like this is you can add your Ribber immediately and rib up the foot without having to worry about the bulky weight on the inside of the machine of which the ribber would fight for space with.

Dean and Bean fairly recently modelled their version after the fact. With their closed bottom cast on bonnets, this style of weight can offer under project downward weight that won’t get hindered on the inside of the cylinder. This style wright offers an easy toe up weight (after cast on and having worked the toe) allowing for easy clearance if wanting to then add a ribber for a ribbed sock

See other useful images and links: My Ideas and Upgrades | Supplies I Like