Hi and welcome to 2024. I’ve had a long break for a variety of reasons, and I am now coming back to it.

A very kind friend has offered this flatbed to us and so we are now looking at it.

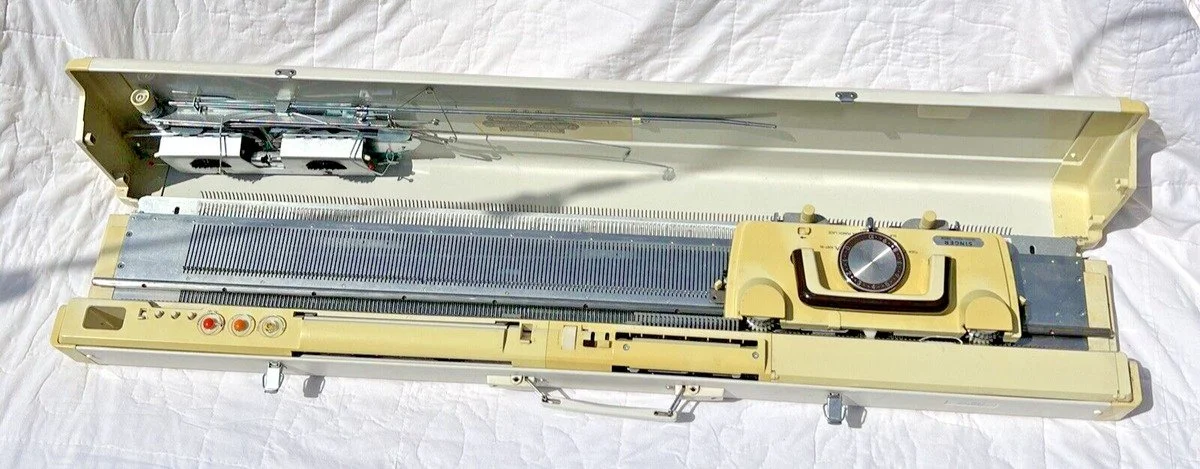

This is a standard gauge machine and is identical in the gauge and brand, that can be knitted as the other flatbed that I have which is an SK 700. I’ve been advised that other than a slight difference in the orientation of the features on the main bed, such as the Punchcard and the contour or knit radar most of the components are identical just in a different alignment as the other machine difference between the machines, however the 700 machines has the main carriage with that is upgraded and easier to move left and right due to added ball bearings which the carriage for the 360 does not have Otherwise they’re pretty much the same featured machine.

(The pictures provided above were from the Internet and it will be eventually replaced-They do not correctly show all the parts that are missing on the machine and this machine did not come with any instruction manuals, but that can be downloaded online)

This machine:

The metal machine bed is showing some concerning areas of rust, and some of the components are very dirty which hints to potential issues on the nether regions of the machine beds.

The 360K standard gauge flatbed / Memo-matic 360

When I opened up the clipped case of the main flatbed, the sinker plate was nowhere to be seen.

This is a component that attaches to the main carriage and cannot knit without it.

Glad I found that missing part in the separate package which contains the ribber. It’s not normally package this way.

The long vertical part that holds the yarn from your yarn source and feeds it over to the carriage. Basically, I call this the yarn mast, was very bent and not secured in the case.

There’s a part called a sponge bar that usually inserts on the main bed from the side - it looks like a long narrow metal ruler with sponge on one side and when correctly inserted with a fresh sponge, it pushes the needles in the right position on the flatbed itself.

For any machine that has sat for a while or has been used for sometime often the first thing one person needs to check is the sponginess or bounce to the sponge on this part - when I pulled this one out, it was completely flat and no longer useable.

The SRP-50 Ribber

In a cardboard much taped box that has seen many a day including some water damage (on the outside the inside). Directly in view in the box when opened was a styrofoam insert with places for the light and heavyweights and a few other components of the machine. Some of the weights are broken. Under the insert is what seems to be a pristine ribber. This component is similar to the main bed, but when correctly set up can offer extra features such as Purl stitches. Well, there are many small components with the machine.

It seems to be lacking table clamps both for just the main bed and the angled clamps you would use if you have the main bed and the river attached not impossible. Those parts probably purchased online from a variety of sources.

I also checked the Sponge bar on the ribber and unlike the same component on a different model that I have (the SRP – 60N) the sponge for this ribber, SRP – 50 uses a very similar sponge bar as the main bed. On my other ribbrr, it uses just a plastic version that doesn’t ever need to be replaced. That’s OK because the ribber isn’t the first thing we should ever start with or use it out of the gate so I don’t have to worry about replacing that component yet as I don’t intend to use it just yet (but it will need to be replaced in order to use it before I use it).

More on this ribber - https://knitmachineparts.co.uk/blogs/know-your-knitting-machine/know-your-knitmaster-srp-50-ribber

Tomorrow, another wonderful friend who has been servicing and cleaning flatbeds will be giving the main bed and the ribber a once over for me.

See all Blog Entries on the BLOG INDEX page